In the Sanafluens mixtures, the water is completely and stably incorporated from the hydration reaction of lime; conversely, in traditional mixtures, a very high part of added water, is free, and evapourating, it leaves gaps in the walls. Sanafluens is based on natural hydraulic lime, sodium gluconate, kaolin, aluminates; it does not contain cement, resins, solvents and radioemissive aggregates.

Consolidation through injections of brick, stone or mixed masonry, "bag" structures, masonry damaged by the earthquake. Consolidation of masonry affected by capillary rising damp and soluble salts. Consolidation of plasters detached from the masonry support, even with frescoes or of historical and artistic value. Consolidation of foundation structures, pillars, vaults and arches.

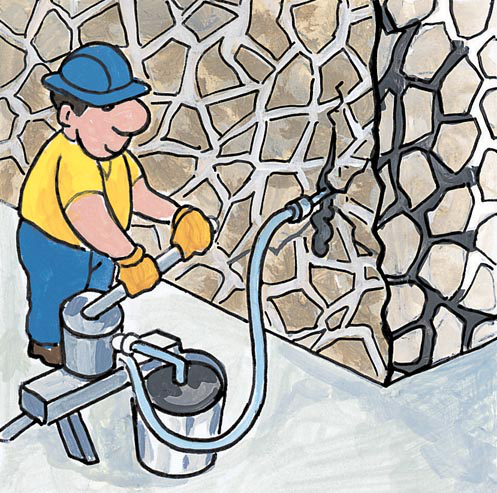

Clean the application surfaces by spraying abundantly with water. If there is a lack of plaster, apply a suitable render of hydraulic lime and sand (such as Untersana) to close as much as possible the escape routes of the grout once it has been injected. Trace, from bottom to top and from left to right, a 50 cm square grid. On the intersection of the squares, drill the masonry with a rotary drill, with a bit of suitable diameter (depending on the type of masonry to be injected; diameter usually between 12 and 24 mm), to a depth of at least 3/5 of its thickness, tilting the drill downwards by about 10 - 20°. Once all the holes have been drilled, they will be sucked up, blown with compressed air and sprayed with water, to remove the dust inside them produced by the drilling. Insert in the holes for a depth of about 5 cm, transparent meshed rubber tubes, with a total length of at least 30 cm (therefore with about 25 cm external). Properly seal the perimeter of the pipe with Anchorsana Fix accelerated setting grouting mortar to prevent the injected product from escaping. Inject the grout always keeping it lightly mixed and operating a continuous flow, without interruptions.

Mixing: Mixing Sanafluens must be carried out with a high-efficiency mechanical mixer (e.g. double-helix whisk with speed variator), starting mixing at a low speed, gradually increasing the speed up to a speed > 300 rpm and respecting the minimum/maximum water proportions (from 21% to 24% referred to the weight of the premix) and mixing for at least three minutes. Sanafluens acquires its exceptional flow characteristics only after effective mixing. Mix for at least 3 minutes, let the mixture rest for one minute and perform a final mix for a further minute. Once the correct workability has been obtained, before proceeding with the injection, it is recommended to pass it through a sieve with a 2 mm mesh (or similar) to intercept any lumps present in the mixture. It can be done by gravity or with mechanical means, always proceeding from the holes located at the bottom towards the upper ones and with limited pressures (always less than 1.5 atm). Therefore, choose mechanical means with the possibility of regulating pumping at low pressures. The pot life of the mixture is extended (> 1 hour) but it is recommended, during breaks in processing, to keep the mixture stirred and not to use material that has been mixed for more than 2 hours because, even if not visible to the naked eye, its exceptional characteristics of flow and penetration into micro-cavities and micro-cracks begin to disappear. To check the injectability on site, the grout must come out of the pipes adjacent to the one in which the injection is being carried out.

Compressive strength

UNI EN 1015-11

Flexural strength

UNI EN 1015-11

Chloride content

UNI EN 1015-17

Water penetration after capillary absorption

UNI EN 1015-18

Bonding force

UNI EN 1015-12

Thermal conductivity

EN 1745

Static elastic modulus

Permeability to water vapor

EN 1745

Capillary absorption

UNI EN 1015-18

Density

UNI EN 1015-6

Approximately 1500 kg of Sanafluens for each cubic metre of volume to be filled.

An abundant preliminary injection of water into the holes drilled in the masonry is recommended, to allow an adequate and rapid sliding of the grout.

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.