Syntech Poliurea Spray - FC

Resistance to laceration: 100 +/- 5 KN/m

Tensile strength: 20 +/- 2 Mpa

Advantages of the system:

- Safe application even on irregular substrates, vertical or with large slopes.

- Possibility to create continuous layers, free of critical protuberances created by common joints.

- Possibility to create high performance, very thin layers, with low specific weight.

- Possibility to perform maintenance and/or repairs easy and efficiently.

Fields of application

Syntech Poliurea Spray - FC is particularly used as waterproofing on concrete or as a protective coating for water containment tanks, primary containment, driveways and parking lots, purification plants, EPS coating, coating and protection of sheet metal, roofs, balconies and canopies in wood, tanks and pools, seamlessly without interruptions.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Prefabricated concrete

Drywall

Plaster (gypsum)

Wood

Metal surfaces

Fiber-cement

Tiles

Floor screed

Rock walls

EPS

Polystyrene

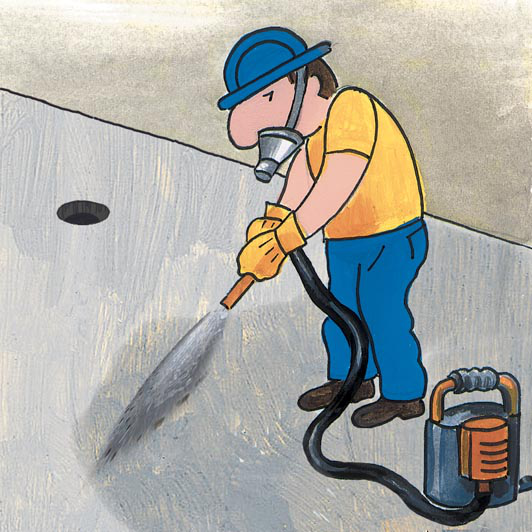

Preparation of supports

The support on which the polyurea system must be laid must be suitable for withstanding the stresses resulting from the intended use, such as static or dynamic loads, impacts, thermo-hygrometric dilations, vibrations, etc. As regards the characteristics of the substrate (maximum humidity, cohesion, strength class, flatness, etc.) and the preparation of the surface that will accommodate the resin system, we recommend the requirements set out in chapter 5 of the UNI 10966 standard ("RESIN SYSTEMS FOR SURFACES HORIZONTAL AND VERTICAL - INSTRUCTIONS FOR DESIGN AND APPLICATION "). In any case, carefully clean and degrease the surfaces, removing any kind of dirt, paint residues or incoherent parts. The humidity of the support must be <= 3%. Evaluate the most convenient type of mechanical preparation (shot peening, sandblasting, hydro-washing, etc.). The surfaces must also be free from discontinuity, and possibly leveled and regularized with products from the FLOOR line or the REPAR line. In case of presence (even suspected) of humidity deriving from capillary rising from the substrate, it is recommended to apply in advance the epoxy resin for "wet substrates" Syntech Pavidamp. Tiled floors, or floors covered with pre-existing resin, must be subjected to mechanical roughening carried out with shot blasting, milling, bush hammering, etc., until the total elimination of the waterproof crust and the opacification of the surfaces. Remove dust after abrasion.

It is recommended to use Primer from the SYNTECH POLIUREA PRIMER range. On particularly absorbent substrates, to avoid the formation of craters / blowholes on the surface of the freshly sprayed product, it is recommended to use primers from the SYNTECH POLIUREA PRIMER range, always contacting the Azichem technical staff for clarification on the most suitable type to use. Apply several layers of primer until the porosity is saturated and providing a light dusting with clean and dry quartz sand (0.4-0.7 mm). Never dust off the primer. Provide suitable elastic sealing systems to cover joints, fittings, cracks or fissures subject to significant movements.

Mode of use

Pure polyurea Syntech Poliurea Spray - FC requires a bimixer system capable of producing pressure above 180 bar and temperatures above 65°C. Contact Azichem technical staff for clarification on the best gun to use and details of the system air.

Application methods

Two-components hot sprayer

Technical specifications

Hardness

UNI EN ISO 868:2005

48 +/- 3

650 +/- 200 (A) - 400 +/- 200 (B) mPas

Permeability to water vapor

0.025

Concrete adhesion (cutting test)

UNI EN 1542:1999

> 1.5 MPa

Longitudinal elongation at break

ISO 527-1:2012

370 (+/- 30) %

Consumption

From 2,00 to 2,50 kg of SYNTYECH POLIUREA SPRAY - FC for each square metre of surface to be covered.

Packaging and dimensions

Barrel 225 kg [A]

Barrel 205 kg [B]

Kit: 1 Barrel 225 kg [A] + 1 Barrel 205 kg [B]

Storage and conservation

Protect from freezing.

Warnings

See the safety data sheet to view the complete data. Protect materials from humidity and water.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.