Repar SM Bic and a plaster end, two-component, thixotropic, rheoplastic, composite , "multipurpose"; based on high-resistance cements, superpozzolanic fillers, hydrodispersed polymeric resins, plasticisers, stabilisers, and anticorrosives, antiallergic additives, selected aggregates, microfibres. The very fine binding matrix, with a high pozzolanic component, together with the special polymers contained in component B, give the applied product a high adhesion to the support, together with a particularly low elastic modulus. The fine grain size and spheroidal morphology of the quartz aggregates facilitate the application of the smoothing compound, especially when used in combination with GFRP meshes (Rinfor System anti-tipping and anti-shattering systems).

• Repairs, smoothing, protective and waterproofing coatings, planar regularizations, adhesive coatings, etc., on cementitious supports, walls, cement plasters, concrete floors, even low-absorption coatings (plastic wall coatings, provided they are firmly anchored to the support).

• Smoothing of reinforced concrete structures of tanks, tanks and swimming pools, before installing resin coatings or tiles.

• Smoothing of beams, pillars and decks of road infrastructures

• Rinfor System anti-tipping system on partition walls and infills, in combination with GFRP Armaglass Structura 115, Armaglass Structura 250 meshes and connectors in GFRP Armaglass Connector or in Helix Steel Aisi 304 stainless steel.

• Rinfor System shatter-proof system on floors, in combination with Armaglass Structura 250 GFRP mesh, flanges with screws and brackets with plugs.

• Regularization and preparation layers of concrete and masonry supports before the installation of carbon fiber FRP systems, both impregnated in situ (fabrics) and glued (sheets).

Application surfaces should be clean, free of soiling, crumbling and non-adhering parts, dust, etc., conveniently saturated with water until they reach the condition "saturated with dry surface".

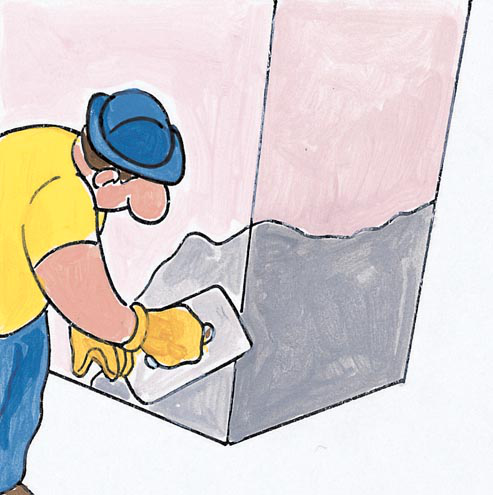

Mix the concrete powder (component A) with the polymeric hydrating dispersion (component B), preferably with a mixer at a low number of revolutions, gradually pour the powder into the liquid (in case of manual mixing add the liquid to the powder); continue to mix until a homogeneous lump-free mixture is obtained. The optimal consistency of the product and the consequent physical-mechanical performances declared in this technical data sheet can be reached using 4.5 kg of COMPONENT B for each 25 kg bag. The excess quantity of COMPONENT B (0.5 kg) is particularly useful for priming the substrate, or for wetting the trowel in the final smoothing operation, or in hot and arid environmental conditions where the mixed product is kept at rest in the bucket it may require some light addition of liquid to regain its optimal consistency, thus avoiding uncontrolled water additions.

Compressive strength

UNI EN 1015-11

Flexural strength

UNI EN 1015-11

Bonding force

EN 1542

Darcy impermeability

Reaction to fire

pH

Static elastic modulus

EN 13142

Density

UNI EN 1015-6

Capillary absorption

UNI EN 13057

Thermal compatibility

EN 13687-1

Approximately 2.0 kg/m² of Repar SM Bic for each millimetre of thickness to be made.

Do not apply in case of direct exposure to sunlight; cure the protection and the prolonged moist hardening of exposed surfaces.

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.