Fields of application

Precision anchorage of operating machines: presses, turbines, power supply units, rolling mills, alternators, overhead cranes, metal structures, tracks, etc.. Structural adaptation, renovations, drawing and reinforcements, using injections and castings inside formworks. Creation of connection anchorage using steel bars with a diameter and depth consistent with the project specifications, by casting in specifically prepared perforations. Construction of structural road joints.

Allowed supports

Concrete

Prefabricated concrete

Mixed walls (bricks and stones)

Rusty reinforcement rods

Preparation of supports

The application surfaces should be clean, free of containment, inconsistent and incoherent parts, dust, etc., conveniently saturated with water to reach the "saturated to dry surface" condition. An adequate roughening of the surfaces by scarifying, sandblasting etc. is always necessary in order to obtain the maximum adhesion values to the substrate. The optimal values are obtained with high pressure hydro-scarification. Bare the irons undergoing disruptive oxidation or deeply oxidized, removing the rust of the exposed irons (by sandblasting or abrasive brushes).

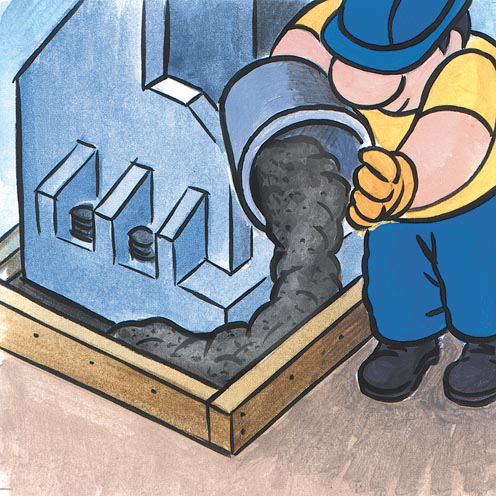

Mode of use

Place 2/3 (approx 2.5 litres per bag) of the total water in the mix, then gradually add the product and the remaining water, mixing until you obtain an even mix with the desired consistency and no lumps.

Technical specifications

Compressive strength at 2 days

UNI EN 12190

> 65 N/mm²

Compressive strength after 28 days

UNI EN 12190

120 N/mm²

Flexural strength after 28 days

UNI EN 196/1

> 17 N/mm²

Breaking load longitudinal

> 6 N/mm²

Access for traffic light

a 20° C

24 h

Access with maximum stress

3 day

Bonding force

UNI EN 1542

> 3 N/mm²

Static elastic modulus

EN 13412

37000 N/mm²

Water penetration under pressure (5 bar for 72 hours)

UNI EN 12390-8

3 mm

Measuring the flexural tensile strength (limit of proportionality, residual) fr1k (gap opening 0.5 mm)

10 N/mm²

Measuring the flexural tensile strength (limit of proportionality, residual) fr3k (gap opening 2.5 mm)

7 N/mm²

Endogenous withdrawal

T 20 °C e U.R. 50%

< 0.05 %

Free-phase withdrawal/expansion

100

Resistant to freezing/thawing cycles in the presence of salts/chlorides

Thermal conductivity

UNI EN 12664

0.85 W/mK

Consumption

Approximately 1900 kg of Grout 2 SFR for every cubic metre of mixture to be made.

Packaging and dimensions

Bag 25 kg

Pallet: 50 x (Bag 25 kg)

Storage and conservation

Store the product in its original packing, in a fresh and dry environment, avoiding frost and direct sunlight.

Warnings

Given the self-levelling properties of the product and its self-compacting capacity, you are advised to pay due attention to the vibration phase. Excess zeal in the vibration operation could worsen the aesthetic performance of the resulting manufactured work.

Do not use in the absence of adequate side confinements.

Ensure protection and damp seasoning of the surfaces exposed.

Implement casting procedures capable of ensuring the absence of vacuums and cracks; grout the mortar from one part of the perimeter of the casting to avoid air sacks.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.