Fluid cone after mixing 0'

EN 445

Exudation

EN 445 3 h

Fluid cone after 30'

EN 445

Water/binder ratio

Volume variation with cylinder method

EN 445

Density

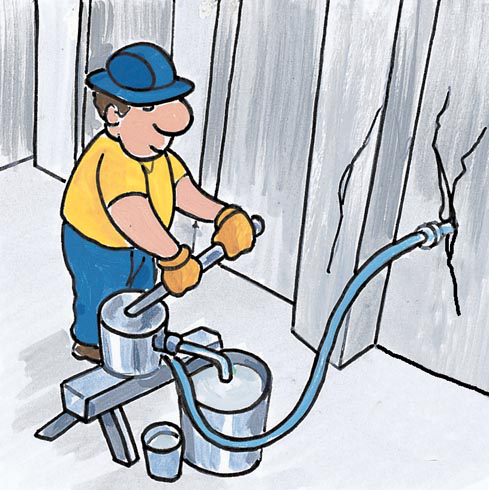

mix

Adherence to steel

The binary mixtures for strengthening injections, based on hydraulic binders + water must be packaged with the addition of the specific compound stabilizer, superlubricant, superpozzolanic Fluid Cable by AZICHEM srl, characterised by moderate expansion in the plastic phase, with a variable dosage by weight, on the weight of the binder, between 6 and 10%.