Syntech PU Foam 60

Syntech PU Foam 60 guarantees excellent adhesion with the support, giving rise to a continuous membrane, without any joints and extremely resistant:

- It adapts to any geometric shape

- Friendly to the environment, they are inert and disposable materials.

- It does not weigh down the structure

- Low permeability

- Best thermal insulator

- Reduction of thicknesses compared to other insulators

- Cancellation of thermal bridges

- Long service life - useful life of more than 50 years

- Excellent compressive strength

- Resistant to biological attack and does not favor the growth of fungi and bacteria

Fields of application

Syntech PU Foam 60 is particularly used for:

- Thermal insulation on buildings, attics, ceilings

- Waterproofing after using top coatings

- Foundation lining

- Coating of tanks and reservoirs

- Coating of isothermal vans

- Protection of ducts and pipes

- Cold room lining

- Coating and protection of sheet metal

Allowed supports

Concrete

Prefabricated concrete

Wood

Metal surfaces

Fiber-cement

Glass

Steel

Preparation of supports

All surfaces must be free of contaminants and humidity below 3%; it must offer a mechanical grip on a solid and non-yielding support. Where necessary we recommend a preparation carried out with shot blasting, bush hammering, sanding or water washing. Consult the staff for proper preparation of the substrate. If necessary, it is recommended to use primers from the SYNTECH family and contact the staff for clarification on the most suitable type to use.

Mode of use

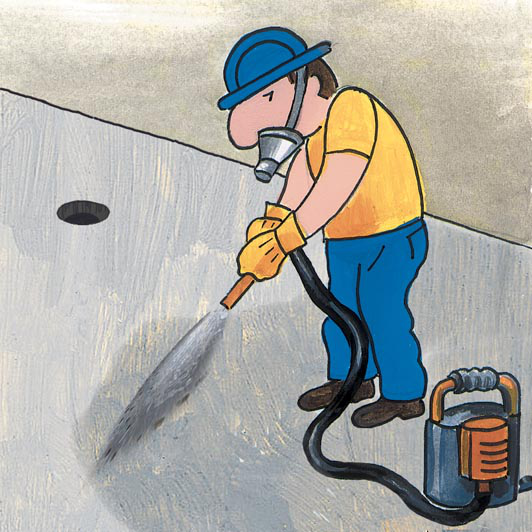

Syntech PU Foam 60 requires a bimixer system capable of producing pressure over 160 bar and temperatures over 60 °C, equipped with transfer pumps with a 3:1 ratio. Contact the staff for clarification on the best gun to use and details of the air system.

The two components must be preheated to around 30 °C by heating bands.

Syntech PU Foam 60 must be sprayed at pressures that fall within the 140-160 bar range and at temperatures that can vary from 35 to 45 °C.

It is the responsibility of the applicator to correctly calibrate the technical equipment and the combination of nozzles relating to the gun, the length of the pipes and the technical parameters of the spray system.

Syntech PU Foam 60 must not be applied in thicknesses greater than 3 cm per coat.

The second coat should not be done before 30 minutes have passed since the previous application, allowing the material to cool.

Application methods

Two-components hot sprayer

Technical specifications

Fire resistance

EN 13501-1:2009

CLASS E

Thermal conductivity

EN12667:2002

0.033 W/mK

Permeability to water vapor

EN 12086:2013

38 μ

Yield of a two-component kit

7 - 7.5 m³

Compressive strength

EN 826 :2013

CS(10\Y)392 kPa

Resistant to chemical agents

Capillary absorption

EN 1609:2013

0.019 kg/m²

Touch hardening at 20°C

EN 14315-1:2013

14 s

Consumption

Approximately 0.650 kg of Syntech PU Foam 60 for each square meter of surface to be coated and for each centimeter of thickness to be created.

Available colors

Neutral tending to yellow

Packaging and dimensions

Barrel 250 kg [A]

Barrel 220 kg [B]

Kit: 1 Barrel 250 kg [A] + 1 Barrel 220 kg [B]

Storage and conservation

Protect from freezing.

Warnings

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.