Syntech HAG Pompa AZ-PT/B

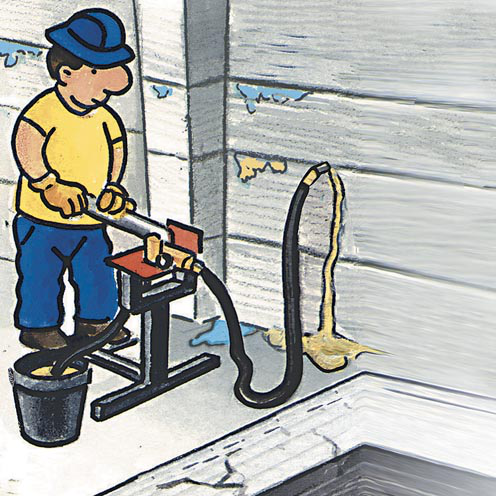

The pump AZ-PT/B has a bulk at the base of maximum 65x110 cm, and is equipped with an extensible telescopic stand, in order to adjust the height as a function of the ergonomic requirements of the operator who uses it. The height from the ground varies from 85 cm to 125 cm.

Fields of application

Masonry injections of hydro-expansive polyurethane resins for stopping water infiltration and/or fluid epoxy resins for masonry reinforcement.

Allowed supports

Concrete

Bricks

Tuff

Mixed walls (bricks and stones)

Stone walls

Preparation of supports

Install the injectors SYNTECH H.A.G. INIETTORE 120 and SYNTECH H.A.G. INIETTORE 170, as specified in the respective technical data sheets.

Mode of use

Connect the high-pressure hose supplied with the pump to the special injector, which is suitably installed in the masonry. Immerse the suction pipe supplied with the pump (reinforced plastic pipe) in the container (bucket, bottle, etc. ) containing the resin to be injected. Insert the pressure relieving tube (transparent plastic tube) in the same container. Start the injection operations, by pumping the resin in the injectors by activating the pumping lever.

Upon saturation of the cavity to be injected, the pressure of the injected liquid will be such as to impede the operation of the lever; at that point it will be necessary to totally relieve the pressure by operating the appropriate vent cock. Disconnect the hose from the injector used and connect it to a new injector. Repeat the procedure for each intended injector.

At the end of each injection operation and before storing the pump, it is strongly recommended that you clean it carefully by first circulating Nitro thinner in the hydraulic circuit for a few minutes, and then by circulating the specific lubricant cleaner SYNTECH H.A.G. CLEANER.

Consumption

Product to buy as needed.

Storage and conservation

Protect from humidity.

Warnings

Do not disconnect the tube still under pressure from the injector used before totally relieving the residual pressure! The pump may reach 40 bar and thus, there is a serious danger of injury if the pressure is not previously relieved as described.

Failure to clean the pump with the measures described above, can cause the total blockage of the hydraulic circuit of the pump, making it temporarily unusable other than after meticulous and thorough cleaning. Total or partial replacement of seals (o-ring) may also be necessary.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.