The main characteristics of Grout iTOP are: • the mix of high-strength superfine binders, combined with micronized silicas with pozzolanic activity, makes the mortar, at the end of the hardening process, intrinsically waterproof and extremely durable against the most severe exposure environments (exposure classes XC = corrosion induced by carbonation, XF freeze-thaw, XA chemical attack, XS and XD corrosion induced by chlorides); • the highly alkaline pH (> 12) protects the reinforcing bars from the onset of corrosion; • the negligible breathability to carbon dioxide provides the hardened mortars with extremely high anti-carbonation characteristics. Ductility, toughness and high tensile strength thanks to the presence of READYMESH PF-180 structural polyolefin fibres (essential characteristics of the fibres: length 18 mm, diameter 0.48 mm, tensile strength 516 MPa) .

For application thicknesses greater than 8 cm, it is possible to add 25% to 35% of Gravel 6.10 (dried gravel, selected, with a grain size between 6 and 10 mm, specifically for addition to structural pourable mortars, in order to improve the grain size curve, based on the increase in casting thickness required); • extremely high fluidity and flow capacity, a key property for ensuring that all spaces are filled in under-plate anchors and in low-thickness formwork castings; • high mechanical performance at both short and long curing times; • high adhesion to concrete and steel.

Grout iTOP is particularly suited to precision anchorages for steel pillars, turbines, compressors, alternators, frontal and horizontal furnaces, milling machines, planers, presses, port cleats, mills, wind turbines, rock cutting machines and machinery generally. In the road works sector, it is particularly apt for anchoring structural road joints and securing road safety barriers.

The applicative surfaces must be clean, free from contamination or any loose or detached parts and dust, being sufficiently rough to permit good mechanical gripping between the surface and the Grout iTOP casting. Sufficiently saturate the foundation concrete with water for at least eight hours before pouring the casting mortar. Remove any surface water with sponges or air jets until it is “saturated with a dry surface”. An adequate roughening of the surfaces by scarifying, sandblasting etc. is always necessary in order to obtain the maximum adhesion values to the substrate. The optimal values are obtained with high pressure hydro-scarification. Bare the irons undergoing disruptive oxidation or deeply oxidized, removing the rust of the exposed irons (by sandblasting or abrasive brushes).

Add two-thirds (about 2.5 litres per bag) of the total water into the concrete mixer, then gradually add Grout iTOP and the remaining water, stirring for 3-4 minutes until a homogeneous mixture with the desired consistency and free of lumps is reached. Grout iTOP can be easily pumped, following proper mixing with the correct quantities of water (we do not recommend pumps with volumetric dosing of water in which the amount of liquid is not well defined and the product is quickly mixed into the pumping circuit). For elevated anchoring profiles, adding Ghiaietto 6.10 is recommended (see the relevant data sheet for more information). The application temperature is to be between +5° and +35° C. Abundantly disarm the formwork to prevent surface imperfections and the subtraction of mixture water (Grout iTOP is strongly adhesive and grips to the various media including wood and steel, if not properly unarmed). Given the self-levelling properties of the product and its self-compacting capacity, paying due attention to the vibration phase is recommended. Excessive zeal in the vibration operation can worsen the aesthetic rendering of the end result. Do not use in the absence of suitable lateral containments. Ensure exposed surfaces are protected and wet-cured. Adopt casting procedures to ensure the absence of voids and discontinuities. Only pour the mortar from one part of the casting perimeter to avoid air pockets.

Compressive strength after 1 day

UNI EN 12190

Compressive strength after 7 days

UNI EN 12190

Compressive strength after 28 days

UNI EN 12190

Flexural strength at 1 day

UNI EN 196/1

Flexural strength after 7 days

UNI EN 196/1

Flexural strength after 28 days

UNI EN 196/1

Steel bar extraction at a load of 75 kN (EN 1504/6)

Concrete adhesion (cutting test)

Capillary absorption

Density

Static elastic modulus

Fire resistance

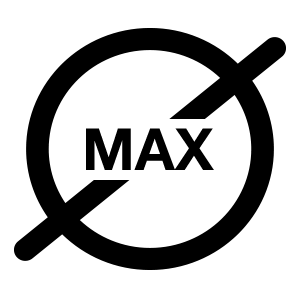

Water penetration under pressure (5 bar for 72 hours)

UNI EN 12390-8

Approximately 19 kg/m² of Grout iTOP for every centimetre of thickness to be implemented (approximately 1900 kg per cubic metre).