Sanawarme

Sanawarme is the highest technological expression of Azichem in the context of renovating plasters. It is a product based on hydraulic lime, botticino, kaolin, calcium caseinate, Vichy salt, calcium carbonate, tartaric acid, ammonium salts, expanded perlite, cork powder and natural fibres. Sanawarme is characterised by high hygroscopic, breathable and thermal/acoustic insulation properties. It is a "thermal mineral coating", natural, for ecological building, that does not contain cements, resins, solvents and radioemissive materials.

The structure of the coatings made with Sanawarme, which is particularly suited to quieten and dissipate, in the form of heat, the acoustic energy inside the pores and "channels", provides interesting performance even in terms of sound absorption which, at high frequencies, reaches values of 1/3, with interesting prospects for acoustic correction of the internal environment (Test Report no. 214705 of August 3, 2006 issued by the institute Giordano).

Fields of application

Applying coating plasters in both new constructions, and in interventions of restoration and renovation of old buildings. Anti-condensation and mildewcide correction for indoor, out of the ground and buried surfaces. Insulation of thermal bridges.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Prefabricated concrete

Wood

Fiber-cement

Bricks

Mixed walls (bricks and stones)

Brickworks

Stone walls

Preparation of supports

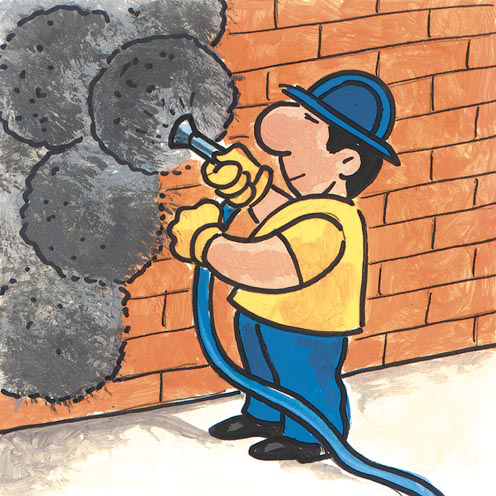

Removal of crumbling plaster, if present. The wall bodies for application should in any case be clean, intact, free from fouling, dust, crumbling and non-adhering parts, conveniently saturated with water until it reaches the condition of "saturated dry surface".

In the presence of salt efflorescence it will be necessary to ensure its careful removal by application of packs of the specific acid detergent and saline converter Deterg-A, in solution with water 1:4. To prevent any new spills of salts, use specific universal anti-saline treatments in aqueous solution, Sanareg, for humid surfaces, or solvent-based, FEST SALZ, for cohesive saline concretions but with perfectly dry surfaces.

Mode of use

Preliminary construction of specific anchoring scratch coats, breathable, made with Untersana. The rendering, applied by "spraying", must provide a rough, corrugated surface, designed to promote the bonding of the subsequent plaster, which must be applied no later than 2-3 days. In the case of wooden surfaces, attach a galvanized steel wire mesh, diameter 2 mm and mesh 5x5 cm, to the support, holding it away from the surface by 2-3 mm. Spray the rendering Untersana by hand or by plastering machine, in order to provide a rough surface, designed to facilitate the application and the adhesion of Sanawarme. In the case of applying the thermal coat Sanawarme on concrete, it is recommended to apply the super-adhesive rendering Repar Plug.

Prepare the plaster, adding Sanawarme, to the mixing water, for approximately 60-70% by weight (8.5 -9 litres per 13 kg bag). Mix thoroughly until it reaches a smooth, creamy, lightweight, lump-free mixture resembling a "compact foam". Apply the thickness required according to the thermal calculation by plastering machine (type PFT model G4, or the like, equipped with lung for light plasters). For small sizes it is also possible to apply it manually with straight edge and plastic mortar.

Regularise the plastered surfaces with fine skim Sanastof for ecological buildings, for an indicative consumption of 4 kg/m². "Drown" in the thickness of the finishing layer the fibreglass mesh Armaglass 160. Successive breathable paints or putty coats (from the series SANAFARBE, SANAXIL or PROTECH SIL) can be applied after approximately 28 days; in any case, after the proper curing of the plaster, depending on the actual environmental conditions, and the loss of initial alkalinity.

Application methods

Finishing trowel

Plastering machine

Pump

Straight edge

Technical specifications

Compressive strength

UNI EN 1015-11

> 3 N/mm²

Flexural strength after 28 days

UNI EN 1015-11

> 1 N/mm²

Thermal conductivity

λ UNI EN 1745 - EN 12664

0.077 W/mK

Breathability

UNI EN 1015-19

9 μ

Total recycled content

UNI EN 14021:2021

4.9 %

Reaction to fire

EN 13501-1

A1

Static elastic modulus

EN 13142

< 3000 N/mm²

Capillary absorption

UNI EN 1015-18

0.35 kg•h^0.5/m²

Consumption

Approximately 4,00 - 4,50 kg/m² of Sanawarme for every centimetre of thickness to be implemented (approximately 420 kg per cubic metre).

Packaging and dimensions

Bag 13 kg

Pallet: 50 x (Bag 13 kg)

Storage and conservation

Store the product in its original packing, in a fresh and dry environment, avoiding frost and direct sunlight.

Warnings

The fresh surfaces, of the plaster set on-site , should be protected from direct exposure to sunlight, from the rain and the wind and must be cured by prolonged moist hardening.

Over 4cm thick, inclusive of Untersana, Sanawarme and Sanastof, it is appropriate to insert in the centre thickness of Sanawarme a galvanized steel wire mesh, diameter 2 mm and mesh 5x5 cm, fixed to the masonry by steel connectors with improved adherence, following a square lattice with 1 metre spacing.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.