After mixing the two components, Repar Tix HG Bic is perfectly workable with manual methods or with spraying machines. The applied and hardened material will have very high adhesion, durability, impermeable to water, with good vapor permeability, high physical-mechanical resistance (class R4 according to UNI EN 1504/3). The product contains migratory corrosion inhibitors in its B component. The thixotropic characteristics of the product allow excellent adhesion and easy spreadability on vertical surfaces, on the lower parts of beams, shelves or slabs, often even on structures indirectly subjected to light vibrations or dynamic stresses during application. It solves the problems of complex reconstructions or restorations, even on difficult-to-grip substrates and for a wide range of applied thicknesses: from a minimum of 3 mm (to be spread with a blade and finished with a trowel) to a maximum of 100 mm. and beyond, naturally in succession of layers of 25-30 mm / each. (for large thicknesses on large surfaces it is always advisable to provide a contrasting net on connectors fixed to the support). It does not require wetting or anti-evaporation protection after application. The superpozzolanic reaction of the peculiar reactive fillers contained in component A, the three-dimensional micro-armor provided by a balanced mix of READYMESH fibers, together with the special polymers and migratory corrosion inhibitors contained in component B, guarantee the hardened product very strong adhesion to the substrate, dimensional stability and maximum durability to environmental aggressions (from carbonation, acid rain, chlorides, sulphates).

• Repairs and protective coatings of hydraulic works (pipes, dams, tunnels, etc.), offshore structures and artefacts in critical situations: chemical-physical aggressions, leaching water, marine atmosphere, etc.;

• structural restoration of pillars, beams, floors and walls in reinforced concrete, including prefabricated ones, subject to high sulphate aggression;

• volumetric reconstruction and bulking of concrete products with thicknesses from 1 to 4 cm, without the need for electro-welded mesh (the surfaces in this case must be appropriately hydroscarified with a roughness level > 7 on the ICRI _ International Concrete Repair Institute scale);

• restoration of the cortical layer of the concrete and repair of the concrete cover detached following the oxidation of the reinforcing irons.

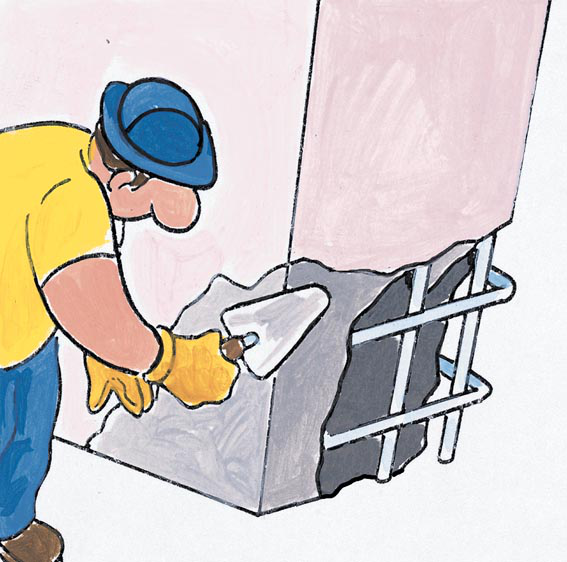

Application surfaces should be clean, free of dirt, crumbling and non-adhering parts, dust etc., and saturated with water "saturated with dry surface". An adequate roughening of the surfaces by scarifying, sandblasting etc. is always necessary in order to obtain the maximum adhesion values to the substrate. The optimal values are obtained with high pressure hydro-scarification. Bare the irons undergoing disruptive oxidation or deeply oxidized, removing the rust of the exposed irons (by sandblasting or abrasive brushes).

Pour component B (liquid) into a container (bucket or other) gradually adding and mixing component A (powder), continue mixing until total elimination of lumps. The optimal consistency of the product and the consequent physical-mechanical performances declared in this technical data sheet can be reached using 4.5 kg of COMPONENT B for each 25 kg bag. The excess quantity of COMPONENT B (0.5 kg) is particularly useful for priming the substrate, or for wetting the trowel in the final smoothing operation, or in hot and arid environmental conditions where the mixed product is kept at rest in the bucket it may require some light addition of liquid to regain its optimal consistency, thus avoiding uncontrolled water additions.

Compressive strength after 1 day

UNI EN 12190

Compressive strength after 7 days

UNI EN 12190

Compressive strength after 28 days

UNI EN 12190

Flexural strength at 1 day

UNI/EN 196/1

Flexural strength after 7 days

UNI/EN 196/1

Flexural strength after 28 days

UNI/EN 196/1

Resistance to carbonatation

UNI EN 13295

Chloride content

UNI EN 1015-17

Density

Static elastic modulus

EN 13142

Bonding force

UNI EN 1542

Capillary absorption

UNI EN 13057

Reaction to fire

EN 13501-1

Approximately 19,50 kg/m² of Repar Tix HG Bic for every centimetre of thickness to be implemented (approximately 1950 kg per cubic metre).