Rasocoat

Rasocoat is a gray color normal hardening smoothing compound with a maximum grain size of 0.6 mm, fiber-reinforced with Readymesh PM polypropylene microfibers. The particular composition gives the mortar obtained, by mixing Rasocoat with water only, high adhesive power even on difficult surfaces, high smoothness in application with a smooth trowel and easy surface finishing with a metal trowel or sponge float.

Fields of application

Regularization and finishing of concrete walls, cement-based plasters or cement-lime mortar, before painting. Smoothing of plastic scratched as long as they are consistent, clean and well anchored to the substrate. Smoothing of tiled walls as long as they are firmly anchored to the substrate and after careful cleaning. Skimming of mineral wood panels (Eraclit® type). Smoothing of HPFRC conglomerates and very low porosity mortars. Realization of smoothing, coatings and gluing in thermal insulation systems, including constructions with expanded polystyrene panels. Skim coat capable of transferring stresses and incorporating ARMAGLASS STRUCTURA fiberglass meshes in the RINFOR SYSTEM 3 anti-tipping masonry system.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Fiber-cement

Brickworks

Stone walls

Tiles

Thermal insulating panels

Acrylic wall coatings

Preparation of supports

The application surfaces must be clean, free of dirt, crumbly and incoherent parts, dust, etc. If the substrate consists of a scratched plastic or tiles, these must be consistent and well adherent to the substrate. Wash all the surfaces subject to the intervention with water in order to eliminate dusty residues that prevent proper adhesion. Absorbent substrates, such as plasters or concrete, must be thoroughly moistened with water, while substrates that are not porous or not porous, consisting of scratched plastic, tiles or HPFRC conglomerates, must be dry at the time of application. In any case, remove the surface water veils with compressed air or rags.

Mode of use

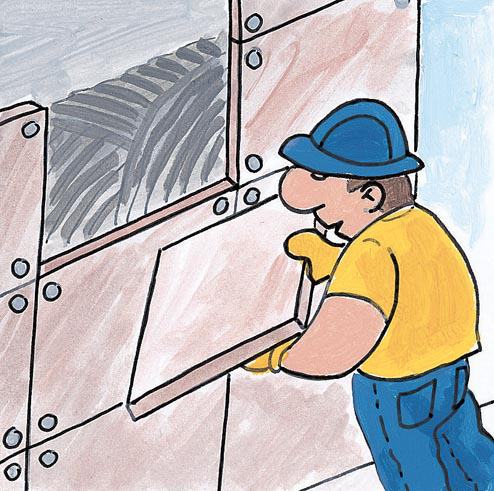

Pour 2/3 of the total mixing water into the mixer, then gradually add the product and the remaining water, mixing until a homogeneous mixture of the desired consistency and free of lumps is obtained. Let the mixture rest for about 1 minute and then proceed with a further short mixing. Spread with a blade, smooth or notched metal trowel in the manner specific to the specific application and paying attention to the following procedures:

- In the application of gluing the polystyrene panel, wait at least 24 hours (at 20 ° C), before proceeding to the following processing (smoothing, etc.).

- In smoothing applications, do not exceed the overall thickness of 4 mm for each coat. The use of the Armaglass 160 alkaline-resistant fiberglass mesh is recommended. The mesh must be pressed with a smooth spatula on the still fresh mix, with the warning to create overlaps of at least 10 cm between the different mesh sheets (or in the joints between one panel and the next in the case of smoothing on heat-insulating panels). Once the first layer of Rasocoat has dried, proceed with the uniform application of the next layer.

The consumption for gluing the panels is about 5-6 kg / m². Consumption for a normal two-coat reinforced leveling coat with a total thickness of 2 mm is approximately 3-4 kg / m².

Consumption for reinforced leveling compounds in anti-tipping systems is approximately 8-10 kg / m².

Application methods

Brick trowel

Finishing trowel

Sponge float

Spatula

Notched finishing trowel

Technical specifications

Compressive strength after 1 day

UNI EN 1015-11

> 4 N/mm²

Compressive strength after 7 days

UNI EN 1015-11

15 N/mm²

Compressive strength after 28 days

UNI EN 1015-11

> 20 N/mm²

Flexural strength after 28 days

UNI EN 1015-11

> 6 N/mm²

Bonding force

UNI EN 1015-12

> 1.5 N/mm²

Static elastic modulus

UNI EN 13142

18000 N/mm²

Capillary absorption

UNI EN 1015-18

0.26 kg•h^0.5/m²

Chloride content

UNI EN 1015-17

< 0.01 %

Consumption

As an adhesive: approximately 5.5 kg/m². As a reinforced skim: from 3 to 4 kg/m² in normal skimming coats, from 8 to 10 kg/m² in skimming coats for the RINFOR SYSTEM 3 anti-tip system.

Storage and conservation

Store the product in its original packing, in a fresh and dry environment, avoiding frost and direct sunlight.

Warnings

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.