Protech Sil I - Therm

Protech Sil I - Therm designed above all for buildings and monuments subject to the protection of the Ministry of Cultural Heritage. The binder based on an emulsion of silicones has allowed to develop a microporous filter impermeable to heavy rain, and at the same time permeable to the diffusion of water vapour. Thermal insulation coating that allows the realization of a thermal insulation with the obvious advantages of recovering the thermal mass from the walls and eliminating bridges and thermal changes of the buildings. Due to its high degree of insulation and transpiration, it is widely used to radically solve mould problems, through the synergistic action of fungicide and thermal insulation. It is composed of a water-dilutable silicone resin, acrylic dispersion, with controlled grain size marble grit, fillers, 3M Glass Bubbles, sanitizing additives and pigments, in a content that guarantees the fulfilment of physical parameters such as: permeability, water repellency, CO2 diffusion, etc.

Fields of application

Suitable for any type of mineral support, ideal especially on walls where the growth of mould and algae represents a serious problem. Due to its low thermal conductivity, it is particularly suitable for solving problems of mould and algae on walls exposed to areas of shade and high humidity.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Prefabricated concrete

Fiber-cement

Preparation of supports

SUPPORTS ALREADY PAINTED WITH SILOXANIC PAINT

Remove any stains and proceed with painting with the siloxane coating (it is always recommended to apply a coat of siloxane impregnating agent).

NEW SUPPORTS

Apply a coat of siloxane acrylic fixative diluted from 20 to 60% with water depending on the absorption of the support.

OLD SUPPORTS ATTACKED BY MOLDS

Clean the wall from mould and algae with a steam cleaner, disinfect with Consilex Muffa Cleaner and Consilex Muffa Remover (sanitizer) after a few hours, when the microorganisms have neutralized proceed with the application of a coat of Protech Fix AC - Therm diluted from 20 to 50 % with water. Once dry, proceed with the application of Protech Sil I - Therm.

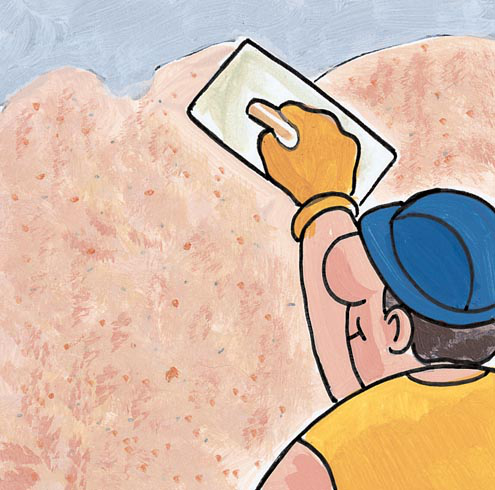

Mode of use

The product is ready to use if necessary add a little water and stir slowly. Apply a coating layer with a stainless steel trowel with a thickness equal to that of the granules it contains. Pass again with a cutting spatula to remove any excess material. After light drying, pass over with a plastic trowel with rotary movements to compact, even out and achieve the full plaster effect.

On large surfaces, it is recommended to apply the product of the same lot and proceed always wet on wet to avoid signs of resumption.

Application methods

Finishing trowel

Sponge float

Spatula

Technical specifications

Solar reflection index (SRI)

ASTM E1980-11

95.2

Complete hardening at 20°C

20°C

24 - 48 h

Degree of water vapor transmission

UNI EN ISO 7783-2

0.3992 FP:A

Thermal conductivity

UNI EN 1745

0.83 - 0.93 W/mK

Consumption

Indicative consumption depending on the different particle sizes of Protech Sil I-THERM available:

1 mm GRAIN: approximately 1.6 -1.8 kg/m²;

1.2 mm GRAIN: approximately 1.8 -2.0 kg/m²;

2 mm GRAIN: approximately 2.4 -2.8 kg/m²;

2.2 mm GRAIN: approximately 2.6 -3.0 kg/m².

The indicated yields refer to smooth supports and are for guidance only. Actual consumption must be identified with a suitable practical test.

Available colors

White

Cartella colori Azichem - silossanici

Storage and conservation

Protect from freezing.

Warnings

Never operate at temperatures below + 5°C. Rainy weather, excessive atmospheric humidity and temperatures below + 8°C, can considerably compromise drying with the possibility of rainwater washout even after several days. In these situations, it is advisable to protect the facades from unpredictable showers, in order not to jeopardize the success of the work. For storage store in tightly closed containers and protect from frost.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.