In radiant panel heating systems , the presence of high air content in the concrete forming the levelling screed can cause the correct spread of thermal energy to be severely obstructed; on the other hand, the conglomerate incorporates air already in the mixing phase in the form of microbubbles, while the excess mixing water and the segregation mechanisms that occur during transport and casting contribute to including additional quantities of air in the form of macrobubbles in the conglomerate. In this context, the peculiar defoamer, superlubricating and antisegregative actions of Fluid Therm, are particularly valuable as they allow the production of grouts and concretes with very low air content.

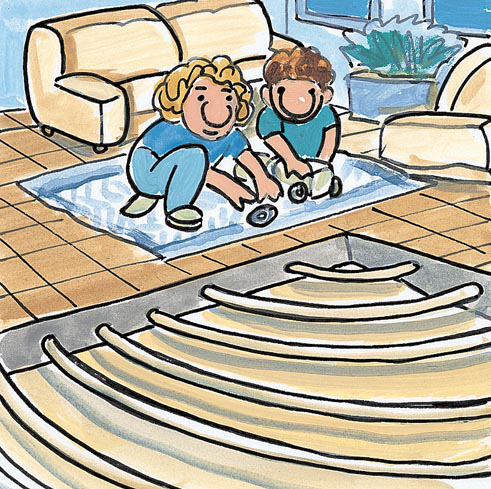

Production of grouts and concrete with "damp earth" consistency, at a low water/cement ratio, with remarkable thermal conductivity properties, for the construction of screeds in radiant panel heating systems.

Fluid Therm must be added to the anhydrous components of the conglomerate, together with the mixing water; the dosage of normal use is 1% by weight, relative to the weight of the binders. After adding the product, provide for adequate mixing in order to obtain a homogeneous mixture free of lumps. To further increase the conglomerate density and improve its anti-cracking performance, you should consider the addition of multifilament polypropylene Readymesh PM-180 or steel Readymesh MM-150 fibre, on the basis of the dosing guidelines listed on the appropriate technical fact sheet. Fluid Therm is considered a neutral additive, i.e. does not involve changes to the normal gripping and hardening times of the conglomerate where it is inserted.

Approximately 2.5 kg of Fluid Therm for every cubic metre of cement mix to be made.

Fluid Therm significantly reduces the mixing water. Check the consistency of the conglomerate in the mixing phase. Excess water can affect the consistency and performance of the conglomerate itself.

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.