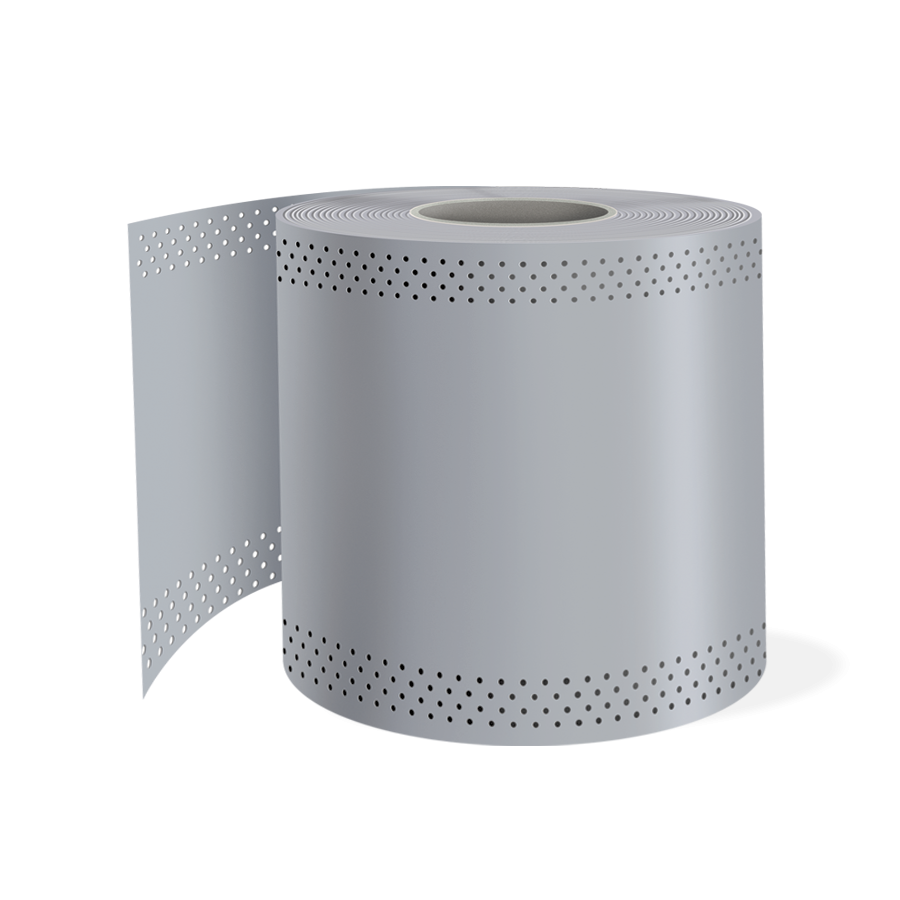

Elastotex 250 Combi

The excellent adhesion with epoxy adhesives such as Syntech AS 21 (AS 31) is greatly improved thanks to the perforated edges that allow a collaboration between the lower layer and the upper layer of resin. SYNTECH AS epoxy fillers allow the gluing of the Elastotex 250 Combi strip on various types of substrates (see paragraph "Preparation of substrates") including pvc supports (see technical document "Adhesion test on pvc sheath").

The strip is flexible and deformable (even at low temperatures) and extremely resistant to traction, root aggression, atmospheric agents and many chemicals. It is easy to lay and this allows for quick, safe and non-hazardous applications for the applicator.

Fields of application

Waterproofing expansion joints, including large ones, subject to considerable work movements, and of natural joints and fissures, also in conditions of hydraulic counter-thrust, in tunnels, silos, tanks, pools, basements, roofing, prefabricated coverings, road joints and hydraulic works in general.

Allowed supports

Concrete

Prefabricated concrete

Metal surfaces

Preparation of supports

The concrete surfaces must certainly be free of incoherent parts, traces of grease, release agent, paints by sandblasting, shot peening, grinding or milling, followed by careful removal of dust. The cement conglomerates must have a minimum tensile strength of 1.5 N / mm2. The curing of the concrete must be at least 3 - 6 weeks depending on the climate. The metal surfaces must be perfectly clean and free from rust, calamine or lamination residues, by sandblasting or equivalent mechanical treatment followed by careful removal of dust (on metal surfaces pay maximum attention to the dew point). The polymeric surfaces must be roughened by sanding. Work areas, edges, etc. they must be delimited with adhesive tape.

Mode of use

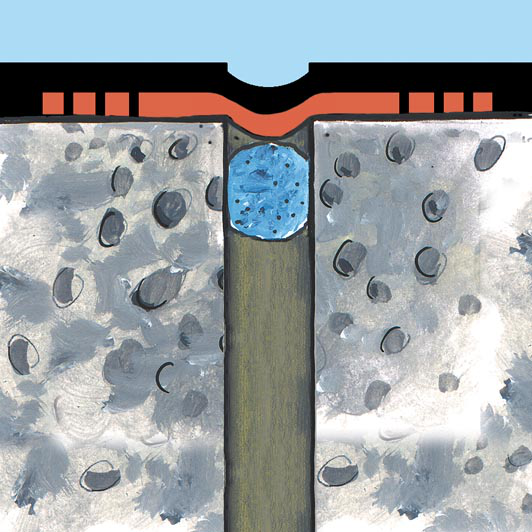

Mix the epoxy resin SYNTECH 21 (AS 31) thoroughly in the pre-determined amount as required (on average roughly 1 kg per meter). Spread the epoxy adhesive prepared as described above, on the sides of the joint to be waterproofed by toothed adhesive spreader, kept constantly clean, taking care to obtain uniformity of the thickness applied that must not be less than 2 mm. Unroll and apply the Elastotex 250 Combi strap, on the fresh adhesive spread, pressing it against the resin, stretching the ends by hand, taking care to avoid wrinkling and air bubbles, until the underlying resin leaks out from the holes on the strap. Apply with a metal filling knife a second layer (at least 2 mm) of Syntech AS 21 (AS 31) adhesive at the edges of the strap, already impregnated, in order to protect it permanently from accidental damage and to obtain certain monolithicity of the end to the support.

For the joint between two adjacent straps, weld the end flaps for overlap and solder them using a special hot air welding machine. For additional security of the seal, a small layer of Syntech AS 21 (AS 31) should be applied on the heated flaps.

The final system resistances will be reached after about 7 days after laying, but already after 24 hours at 20°C, values equal to 60-70% of the final performances can be obtained. In any case the performance after 24 hours will be much greater than those of a high quality concrete.

Application methods

Apply by hand

Spatula

Notched finishing trowel

Technical specifications

Breaking load lateral

EN ISO 527-3

221.8 N / 15 mm

Extension break lateral

EN ISO 527-3

900 %

Resistance to water pressure

EN 1928 B

>4.0 bar

Tensile adhesion with gluing using Syntech AS 21

> 7 N/mm²

Power absorption at 25% elasticity lateral

EN ISO 527-3

42.7 N/mm

Resistance to tearing

EN 12310-2

100 N

Power absorption at 50% elasticity lateral

EN ISO 527-3

49.2 N/mm

Breaking load longitudinal

EN ISO 527-3

241.4 N / 15 mm

Extension break longitudinal

EN ISO 527-3

900 %

UV resistance

EN ISO 4892-3

6500 h

Consumption

1 metre of Elastotex 250 Combi for each linear metre, being careful to overlap the rolls of approximately 5-10 cm in correspondence with the edges of the band to guarantee the permanent water tightness of the system. Consumption of epoxy resin for bonding about 1.5 kg / m.

Storage and conservation

Store the product in its original packing, in a fresh and dry environment, avoiding frost and direct sunlight.

Warnings

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.