Sanaxil Filler

Due to its mineral nature and the chemical adhesion it provides, Sanaxil Filler represents a significant revolution in the traditional concepts of adhesion to supports: it penetrates deeply into the pores, it reacts with the components of the masonry structure creating a homogeneous, indissoluble and breathable "silicated" whole; it does not form films, it is water repellent and resistant to moulds and micro-organisms. When it is applied in combination with paints or putty coats, it substantially improves their durability, because it gives a greater thickness to coatings and paints.

Sanaxil Filler is composed of stabilised potassium silicate, silica aggregates and natural pigments. It has high breathability, excellent mildewcide and antibacterial properties. It has no solvents, thinners, harmful substances in general.

Fields of application

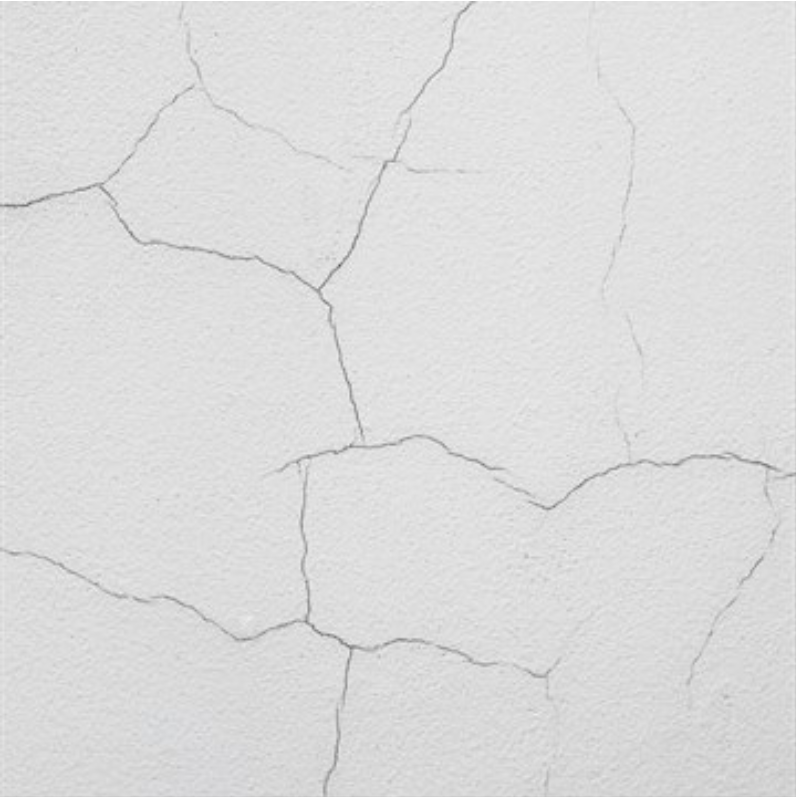

Subbase micro-smoothing, for subsequent coatings with paint or with putty coat, specific for the anti-crackling reclamation of large vertical surfaces of buildings and condominiums in general. It creates of a thick base to improve the durability of the coating.

Allowed supports

Plasters

Concrete

Cement-based or lime-based mortars

Fiber-cement

Paint

Preparation of supports

Application surfaces should be clean, free of soiling, crumbling and non-adhering parts, dust, etc., conveniently saturated with water until they reach the condition "saturated with dry surface".

It is recommended that you preliminarily treat the media with the specific fixative Sanaxil Fix (as such, or diluted with water up to a ratio 1:1).

Mode of use

Sanaxil Filler should only be used for reclamation and under the conditions described above. It can be applied with a roller or brush, possibly after dilution with 10-15% Sanaxil Fix.

Technical specifications

Complete hardening at 20°C

a 20°C

16 - 32 h

Touch hardening at 20°C

a 20°C

4 h

Consumption

Apply from 0.30 to 0.50 kg of Sanaxil Filler per square metre of surface to be treated.

Available colors

White

Cartella colori Azichem - silicati

Storage and conservation

Protect from freezing.

Warnings

During application, protect glass, enamelled metal, aluminium, polished tiles etc., which may be opacified from accidental contact with silicate solutions.

Avoid application in the presence of rainfall and high humidity.

Depending on the temperature conditions at the time of application, and during the drying and dessication phases, colours may vary slightly.The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.