Mauersan

The widespread porosity of Mauersan makes it possible to have adequate expansion chambers for the crystallization of soluble salts (possibly mobilized during the first application phases of the plastering cycle). The Mauersan premix is fiber-reinforced with anti-shrinkage microfibers, it is entirely formulated with raw materials substantially free of soluble salts, it does not contain organic vapor generating substances (VOC) or other raw materials harmful to the health of operators, the environment and the substrates in masonry.

Fields of application

Brick, stone and concrete walls, both old and new, subject to capillary rising damp.

Allowed supports

Bricks

Tuff

Mixed walls (bricks and stones)

Brickworks

Stone walls

Natural stones

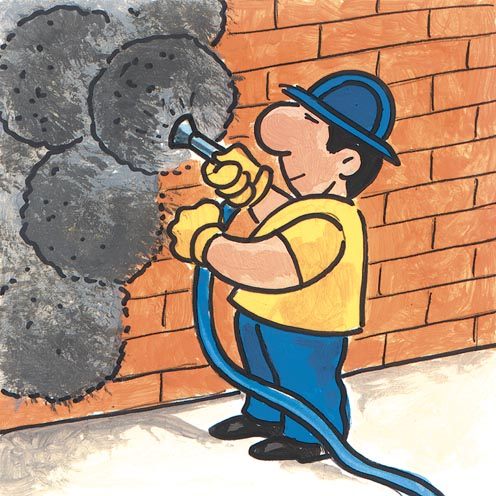

Preparation of supports

• Remove the plaster up to more than 50 cm above any evident humidity or degradation.

• Remove all loose, crumbly or "rotten" joints, remove the joints from bedding mortars when they are excessively crumbly or inconsistent.

• In the presence of surface salts, proceed with scraping and brushing up to the edge of the masonry. In the case of strong saline concentrations deriving from particular conditions (stables, salt deposits, walls in contact with brackish water, environments reached by marine aerosol and other critical situations) evaluate the combination of the dehumidifying plaster with chemical barriers (see technical data sheets of CONSILEX BARRIER A, Consilex Inject Mauer, Consilex Barrier Cream products) and / or extraction packs based on adsorbent clays, and / or spraying of Sanareg saline inhibitor.

• Thorough general cleaning.

• The regularization of the masonry (any alignments and plumbing), the filling of large cavities, etc., will be carried out after the preparation described above using the Untersana mortar, mixed to the right consistency, possibly with the aid of recollections and / or replacements of particularly deteriorated stone elements.

Mode of use

• Where necessary, to promote adhesion of the plaster, apply a transpiring render made with the specific Untersana preparation. The Untersana rough coat, given as a "sprinkle", must create a rough, corrugated surface, capable of favoring the adhesion of the subsequent plaster.

• The application of Mauersan in two coats is recommended. The first coat should be applied a few hours after applying Untersana (swollen but still fresh), to favor a perfect bond between the two products. The second coat must be applied with a uniform thickness when the first coat of INTOBRATHE is well hardened (wait approximately 24 hours between first and second coat). The application can be carried out with manual methods (trowel, trowel) or mechanical spray methods. In the case of applications with a plastering machine, to allow adequate and homogeneous mixing of the product, it is recommended not to use continuous cycle machines.

• Prepare the plaster by adding Mauersan to the mixing water, continuing to mix until the desired mixture is obtained and the complete elimination of lumps. It is advisable to apply a minimum thickness of 2.5 cm. For thicknesses greater than 2.5 cm provide for the insertion of Armaglass Intotech 225 reinforcement mesh.

• Protect fresh surfaces from direct sunlight, rain and wind, take care of prolonged humid curing.

• Regularize the plastered surfaces with a fine, highly breathable lime-based smoothing compound, Sanastof.

Application methods

Brick trowel

Finishing trowel

Plastering machine

Straight edge

Technical specifications

Compressive strength after 1 day

UNI EN 1015-11

> 2 N/mm²

Compressive strength after 28 days

UNI EN 1015-11

5 N/mm²

Flexural strength at 1 day

UNI EN 1015-11

> 1 N/mm²

Flexural strength after 28 days

UNI EN 1015-11

> 2 N/mm²

Thermal conductivity

EN 1745

0.30 W/mK

Reaction to fire

EN 13501-1

A1

Static elastic modulus

EN 13412

< 7000 N/mm²

Permeability to water vapor

UNI EN 1015-19

< 10 μ

Capillary absorption

UNI EN 13057

0.70 kg•h^0.5/m²

Bonding force

UNI EN 1015-12

0.40 N/mm²

Consumption

Approximately 13 kg / m² of Mauersan for each centimeter of thickness to be created.

Packaging and dimensions

Bag 25 kg

Pallet: 50 x (Bag 25 kg)

Storage and conservation

Store the product in its original packing, in a fresh and dry environment, avoiding frost and direct sunlight.

Warnings

The general information, along with any instructions and recommendations for use of this product, including in this data sheet and eventually provided verbally or in writing, correspond to the present state of our scientific and practical knowledge.

Any technical and performance data reported is the result of laboratory tests conducted in a controlled environment and thus may be subject to modification in relation to the actual conditions of implementation.

Azichem Srl does not assume any liability arising from inadequate characteristics related to improper use of the product or connected to defects arising from factors or elements unrelated to the quality of the product, including improper storage.

Those wishing to utilise the product are required to determine prior to use whether or not the same is suitable for the intended use, assuming all consequent responsibility.

The technical and characteristic details contained in this data sheet shall be updated periodically. For consultation in real time, please visit the website: www.azichem.com. The date of revision is indicated in the space to the side. The current edition cancels out and replaces any previous version.

Please note that the user is required to read the latest Safety Data Sheet for this product, containing chemical-physical and toxicological data, risk phrases and other information regarding the safe transport, use and disposal of the product and its packaging. For consultation, please visit: www.azichem.com.

It is forbidden to dispose of the product and/or packaging in the environment.